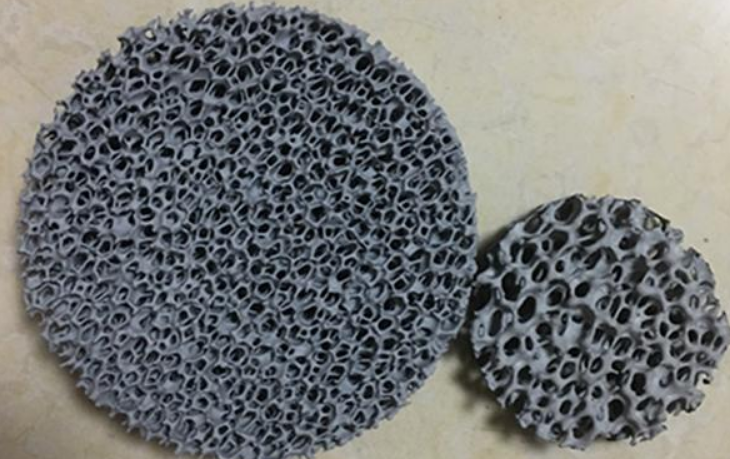

The production process of foam ceramic foam filter needs a drying process, which is achieved by elevated temperature roasting before. But in the casting process, frequently because the temperature control is not good, resulting in elevated rejection rate. The foam ceramic filter low-temperature dryer produced by Omelang can effectively discharge free water and obtain preliminary strength, which considerably improves the qualified rate of the product.

Foam ceramic filter dryer at low temperature was improved on the basis of the heat pump dryers, use air can heat pump as heat energy, cooperate with modular intelligent control system, solved the traditional drying in the light of uneven temperature and moisture are not synchronized, slag and crack caused by the deformation problems, lay a better foundation for bubble volatile period process, product qualified rate raised, The cost will come down naturally.

Foam ceramic filter dryer at low temperature was improved on the basis of the heat pump dryers, use air can heat pump as heat energy, cooperate with modular intelligent control system, solved the traditional drying in the light of uneven temperature and moisture are not synchronized, slag and crack caused by the deformation problems, lay a better foundation for bubble volatile period process, product qualified rate raised, The cost will come down naturally.

Air energy heat pump as a heating host, temperature rises and temperature constant. More energy efficient than traditional drying. It is only 1/3 of the energy consumption of traditional drying. And the whole process does not need to burn wood, coal and other fuels, nor will it produce waste gas, waste slag, no pollution to the environment, to meet the current demand of energy saving and environmental protection in our country.